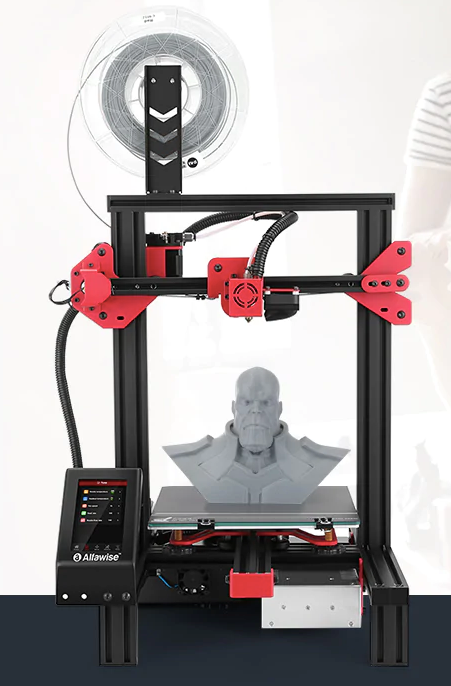

Alfawise U30 Pro

-

1: TMC2208 stepper motor driver

-

2: 4.3 inch touch screen

-

3: The latest open source Marlin firmware

-

4: Product forming size: 220x220x250 mm

-

5: Material diameter: 1.75mm

Alfawise U30 Pro 4.3 Inch Touch Screen High Precision DIY 3D Printer

It’s time to change the rules of the game a bit, since we deal with reprapies, we decided to take a closer look at some cheap popular 3D printers, which could be an interesting alternative to, for example, Anet A8. One of them is the Alfawise U30 Pro printer built on aluminium profiles.

In this way, I bought the Alfawise U30 Pro, a printer costing at the moment $229.99. The printer came packed in an ordinary brown box. At first glance you can see that we are dealing with very legitimate equipment. The printer is fully compliant with all certificates. Thanks to ROSH, we can lick a PCB with electronics (unless it’s against the current) without worrying about our health, because thanks to ROSH we can be sure that it doesn’t contain lead or other toxic stuff.

Seriously, let’s start with the basic technical parameters:

- The diameter of the nozzle is 0.4 mm,

- Working area – 220 x 220 x 250 mm,

- Bowden extruder for 1.75mm filament,

- A 4.3″ LCD touch screen display,

- Built-in end-of-filament sensor,

- Recommended print speed – 30-70mm/s,

- Maximum print speed – 120mm/s,

- Built-in micro SD card reader,

- Electronics powered by 24V,

- Maximum head temperature – 250°C,

- Maximum temperature of the work table – 100°C.

The assembly of the printer itself is trivial, in principle we get the folded whole bottom and our task is primarily to mount the X and Z axes, twist a few muscle profiles and mount the display and the work table. The parts fit together well and we have all the necessary tools in the set. All the fun took me half an hour, including a coffee break. After that time I started the first printout of the card and surprisingly everything worked as it should. A good result. A person who has no previous contact with printers will spend a little more time on it, but it shouldn’t take more than an hour.

As for the quality of the parts used, the only defects I noticed were the untreated holes and the paint falling off near the screws (and it wasn’t the fault of the tightening force, and more so the lack of a washer, the problem also occurred on this one element only).

In the set, after the printer and tools, you will find a sample of the white PLA filament, which (almost) was enough to print a petrol boat. The filament itself is only a few rolls, so the printout is not complete. There is a filament sensor near the extruder. If the filament ends, the printing is automatically paused with the possibility of resuming it.

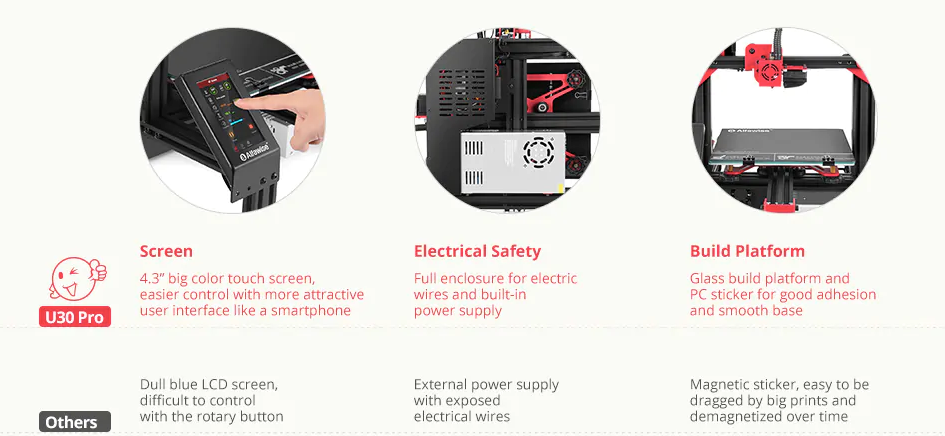

The printer has a touch screen LCD (4.3 inch), which is readable and works quite smoothly, sporadically I had to press something 2-3 times to surprise you. Unfortunately, I don’t know what kind of “touch” it is, but on the screen you can see foil, clearly protruding from it, like in an attic palmtop. The only drawback is the way it is embedded, the display is mounted quite deep in the frame and thus a little less convenient to use when you need to click some element placed e.g. in the corner of the display. Once I also happened that everything went out and the screen was white all the time, maybe it was the fault of the loose display tape.

The memory card (micro SD) is mounted….not in the display, but on the back of the printer housing, which is a bit tedious and slightly incomprehensible to me. But you bought a U30 Pro – you have to live with it.

When it comes to electronics and its wiring, the printer comes armed with a ready-made beam and our task is only to connect three motors, two ends, a filament sensor and table plugs and to plug in the display tape. The cables are described, so if we can distinguish the X-axis from the Y-axis, we will surely manage. We don’t even have to touch the electronics board itself, but knowing that you will be looking into what’s inside, I decided to unscrew a few screws and show what we have.

The printer has a Z-axis with a propeller on one side only, I think the next print section will take a closer look.

To sum up, I can confidently recommend the Alfawise U30 Pro 3D printer to a beginner, and certainly to one who is considering buying the Anet A8 Plus, to one who does not want to spend hours over a bag of millions of screws and small parts, or to play with the processing of elements so that they fit together. With a bit of skill even an amateur will start the printout after an hour of work.

SPECS

Product Details

| Features |

The latest open source Marlin firmware for total control of the 3D printer, makers' freedom, e.g. installation of automatic leveling module Ultra-quiet with plug-and-play TMC2208 stepper motor driver, also for smooth operation and precise printing Filament run-out protectionandpower outage protection guarantee successful print 4.3 inch touch screen, over 53 percent bigger than that of U30, with anoptimized user interface, providing instant access to settings and easier control of printing process Efficient heating and uniform temperature provided by the high-power hot bed with aluminum substrate, glass build platform, and PC sticker for excellent adhesion and smooth base of prints |

| Specification |

Brand: Alfawise Model: U30 Pro Type: DIY Material (Frames): Aluminium Extrusion Platform board: Aluminum Base Engraving Area: no Engraving Accuracy: no Nozzle quantity: Single Nozzle diameter: 0.4mm Nozzle temperature: Room temperature to 250 degree Product forming size: 220x220x250 mm Layer thickness: 0.1-0.4mm Memory card offline print: TF card LCD Screen: Yes Print speed: 120mm/s recommended 30-70mm/s Platform temperature: Room temperature to 100 degree Supporting material: ABS,PLA Material diameter: 1.75mm Language: English File format: G-code,OBJ,STL Model supporting function: Yes XY-axis positioning accuracy: 0.0125mm Z-axis positioning accuracy: 0.0025mm Voltage: 24V Working Power: 24V, Remarks: LCD pixel resolution is: 480*272 Host computer software: Cura,Repetier-Host Packing Type: unassembled packing Supporting Paper Size: no System support: Windows, Linux, MAC Laser Lifetime: no Laser Wavelength(nm): no Voltage Range: 110-240V Current (mA): 15000mA Connector Type: USB Certificate: CE,FCC,RoHs |

REVIEWS

Disclaimer Note

Ratings are based on objective reviews from our users.